Citizens of the Information Age rely on computers to make informed decisions. Use of sensors and computers range from monitoring energy consumption of businesses to monitoring health of loved ones. With smart devices, individuals have the power to gain vital information at a moment’s notice and communicate instantly worldwide. Industries and universities are currently putting out new products and research that function in a variety of ways.

The ASSIST Center at NC State University is working with industries to develop self-powered wearable devices people can use for measuring health or surrounding environment. As these devices become smaller, they begin taking advantage of energy-harvesting nanotechnology. This can be similar to self-winding watches except on the nanoscale; for example, taking advantage of thermo-conductive nanotechnology to use temperature differences of the skin and air to produce power.

Growing use of technology in STEM careers and personal lives leads to an increasing need for skills in communications, problem solving, critical thinking, applying scientific principles, as well as collaboration. Through technology, engineering, and design courses, students can gain experiences in practicing industry-related skills. In conjunction with teachers from various districts in North Carolina, professionals from NC State University, and The Kenan Fellows Program, a project that focuses on STEM career skills and microcontrollers was developed.

This project challenges students to design and construct a wearable device which rescue workers (human or animal) can use to monitor health and surrounding environmental conditions.

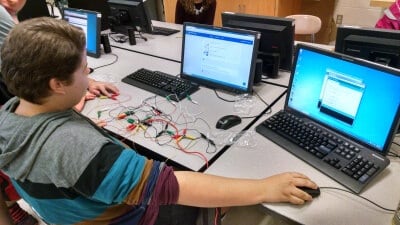

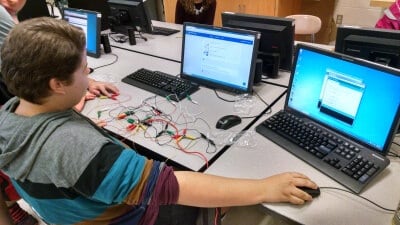

Many devices already exist, such as the ones firefighters use that sound a high-pitched alert when a fellow firefighter hasn’t moved for a certain amount of time or if oxygen levels become too low. Part of the challenge is for students to research existing devices from which they can pull ideas, learn about different power sources for these devices (including nanotechnology), and apply skills in wiring circuits and coding microcontrollers. The equipment available during the project is the Arduino LilyPad, which contains a microcontroller, input devices (button, switch, light sensor, temperature sensor), and output devices (white LEDs, RGB LED, buzzer, and vibration motor). The kits can also come with conductive thread that acts as wiring, a LiPO battery, and means of transferring code to the board.

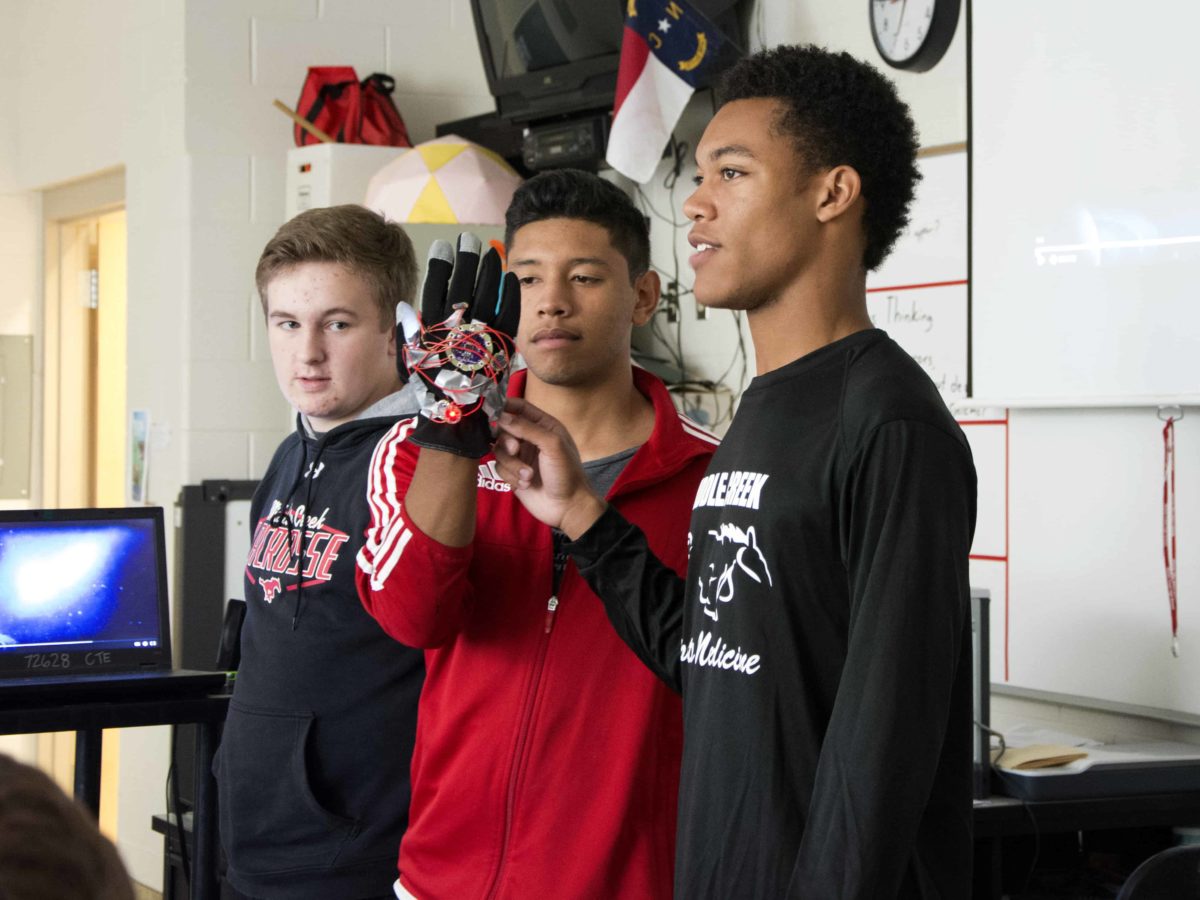

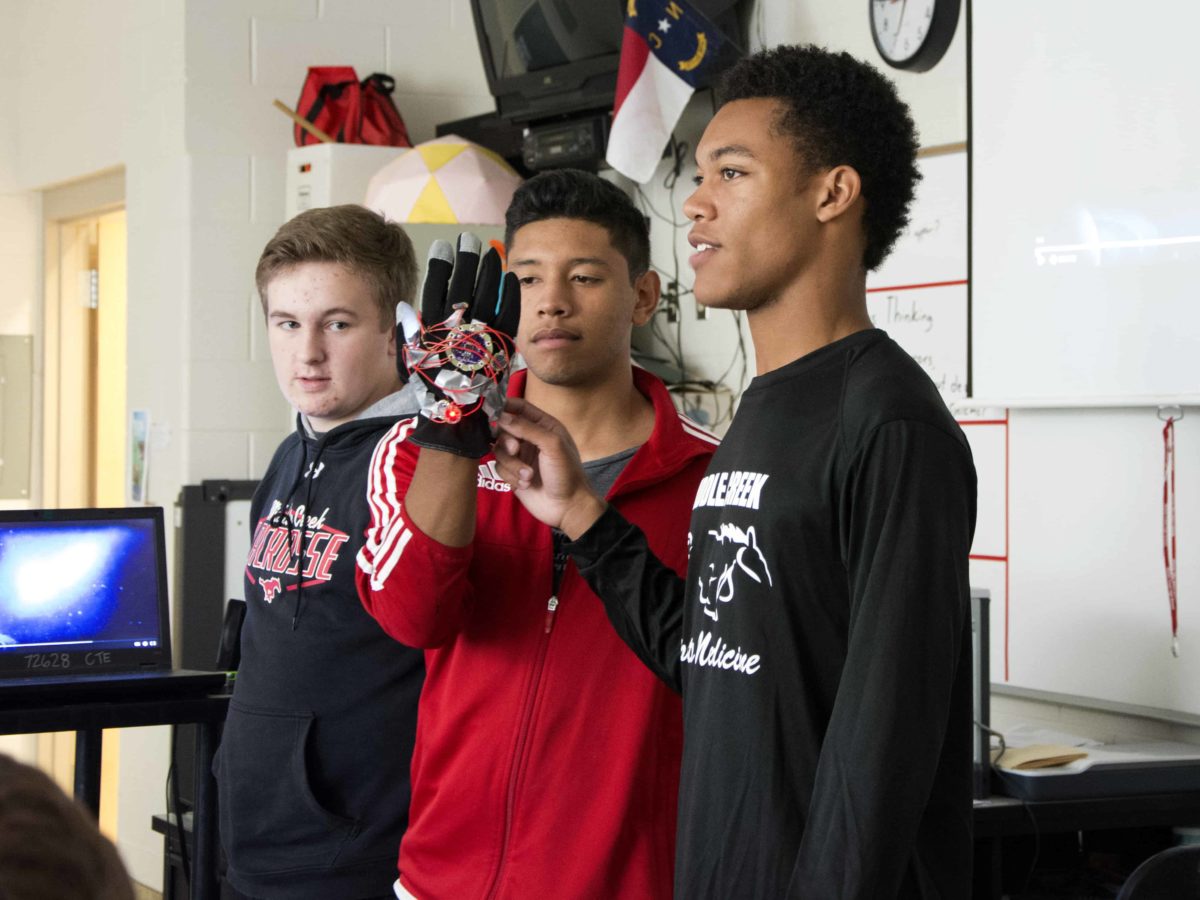

First, students have to research and define the problem. During this time, they also gain knowledge on how to apply basic C/C++ language to control the Arduino board. Students move onto planning their product where they must come up with drawings of the device as well as a program that will control it. Next, they move onto constructing their device by incorporating the board along with input and output devices into a wearable device. It counts as “wearable” if it is an article of clothing (shirt, pants, socks, shoes) or accessory (bracelet, watch, hat, gloves). After building, they test and make improvements. Throughout the process, students must document how they use each step of the Engineering Design Process in a design portfolio and then present it to an audience of peers and professionals.

While completing the project, students found coding initially difficult, which was not surprising since most of them had never done any sort of coding. They were provided an introductory activity where they took an existing program that functioned and they manipulated it to do something slightly different. For example, instead of the controller blinking red at a certain temperature, a student would make it blink blue.

Once they were comfortable with changing simple variables, they could challenge themselves with changing something more drastic. Eventually, students felt more comfortable with the programming to the point they could develop a device. All students were tasked with coding for a few days, but when it came time to working in groups, if a student wasn’t fully comfortable with coding, they were able to work on another aspect of the project (such as the detailed drawing or wiring of the device).

The devices students came up with were very interesting and included firefighting gloves that would monitor ambient temperature and light-up when going into an area with low light as well as a device that a seizure alert service dog could activate to send a signal for help when their owner experiences a seizure.

The project was a success and immersed students in skills they may not experience elsewhere while in high school. Future projects will have students develop CAD models of their designs and possibly require 3D printing part of their project. Other modifications include having students collect data through livestream of their sensors so they can fine-tune coding.

As students work to become professionals in societies heavily using microcontrollers and smart devices, it is beneficial they gain understanding of how such devices function and how such devices make life easier and safer. Industries need individuals who design, monitor, and maintain systems that utilize these devices. By providing hands-on experiences, we can not only prepare students with knowledge of tools they may utilize in the future, but we can also provide opportunities to test the waters of STEM careers they may be interested in pursuing.