Share this story

- “We’re trying to make it as free flowing as possible for our women to go from stability, to safety, to life skills, and then on to further their education. And with the help of A-B Tech, that’s what we are able to do.” #Impact58

- What can a partnership look like between transitional housing and a local community college? This collaboration between @abtech_cc and Transformation Village is educating and preparing residents and non-residents for industry jobs in the region. #Impact58

|

|

The City of Asheville conducted a Point-in-Time (PIT) count on the evening of Jan. 25, 2022. A requirement from the U.S. Department of Housing and Urban Development for communities participating in the Continuums of Care program, the PIT counts the number of people experiencing homelessness in one single night. This includes those who are sheltered in transitional housing, Safe Havens, and emergency shelter.

The count found that homelessness had increased in the city by 21% since 2021.

One of the transitional housing options in Buncombe County is Transformation Village, which provides up to 100 beds for homeless women, mothers with children, and veterans. One of the things that makes the facility special is that the local community college, Asheville-Buncombe Technical Community College, has an entire floor for classes and continuing education within the space.

Transformation Village is part of the nonprofit organization Asheville Buncombe Community Christian Ministry (ABCCM), which looks to address poverty, hunger, homelessness, and access to health care for the under-served population in Buncombe County. ABCCM is made up of over 289 churches of all denominations.

About seven years ago, a conversation started between ABCCM and A-B Tech, said Carolyn Cronin, director at Transformation Village. The big question was: could there be a partnership between the two community-serving entities, and if so, what does it look like and where can it go?

Where it went, was in the building. Cronin said one of the best ways to integrate these women back in the community is through an educational component, and that became, as she put it, “the partnership downstairs.”

“We’re trying to make it as free flowing as possible for our women to go from stability, to safety, to life skills, and then on to further their education. And with the help of A-B Tech, that’s what we are able to do.”

Carolyn Cronin, director at Transformation Village

Manufacturing in the ‘Western Gateway’

A-B Tech’s Advanced Manufacturing department is always looking for direct lines from education to industry. Since the 1960s, they have focused on customized training programs, and the school works directly with businesses and industries in eligible sectors to train their incumbent workers.

For companies that announce they are coming to the region, A-B Tech has the capability to help with recruitment, train those potential employees, and continue to train them based on the needs of the business.

According to this report, A-B Tech had a total economic impact of $405.8 million in the fiscal year 2019-2020. In the Western Gateway region, which includes Buncombe, Haywood, Henderson, Madison, and McDowell counties, manufacturing is the highest grossing industry sector.

Kevin Kimrey, director of economic and workforce development at A-B Tech, said the community college works seamlessly with area economic development groups, taking advantage of opportunities and partnering to create them.

A present and growing economy in western North Carolina is the outdoor industry. Companies are building tents, backpacks, biking apparel, and more. Diamond Brand has been in the region since 1942 and is passionate about sewing. The success of the company depends on it, as they make wall tents, compact tents, bags, and other outdoor gear.

Kimrey and A-B Tech saw the need for an industrial sewing class to meet the demand of employers like Diamond Brand and collaborated with Carolina Textile District to create a robust training program.

Enter the relationship established years prior with the ministry, ABCCM. Sewing was already a popular volunteer class among the residents at Transformation Village, and the opportunity presented itself to house the new program at the facility.

The partnership downstairs

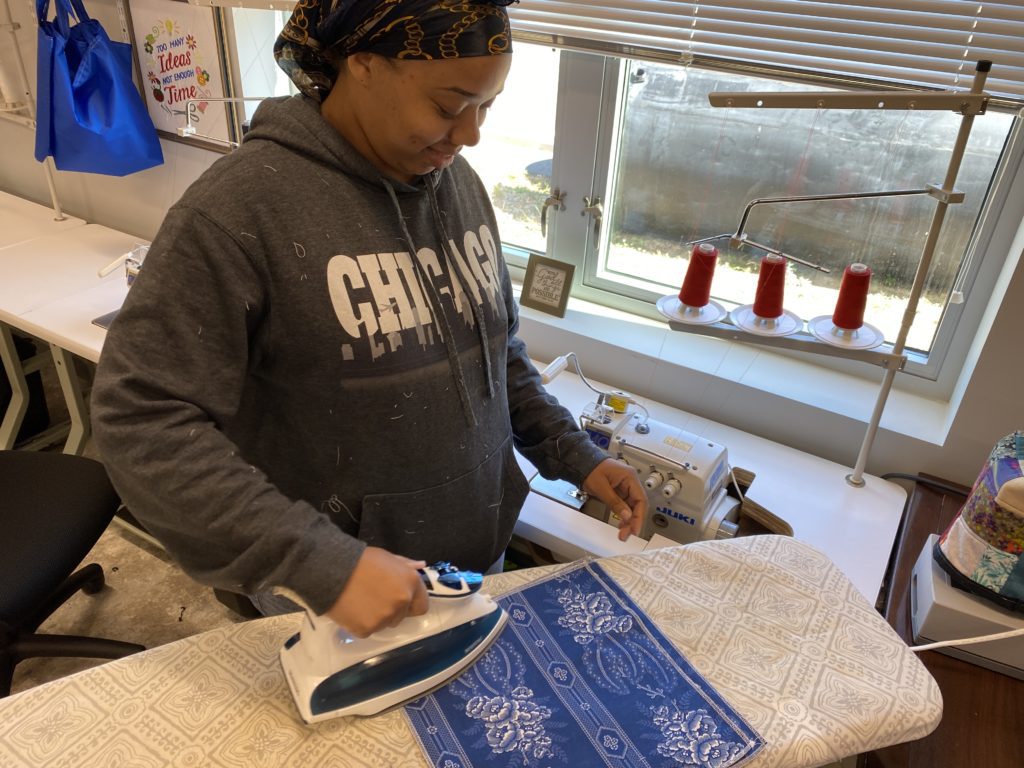

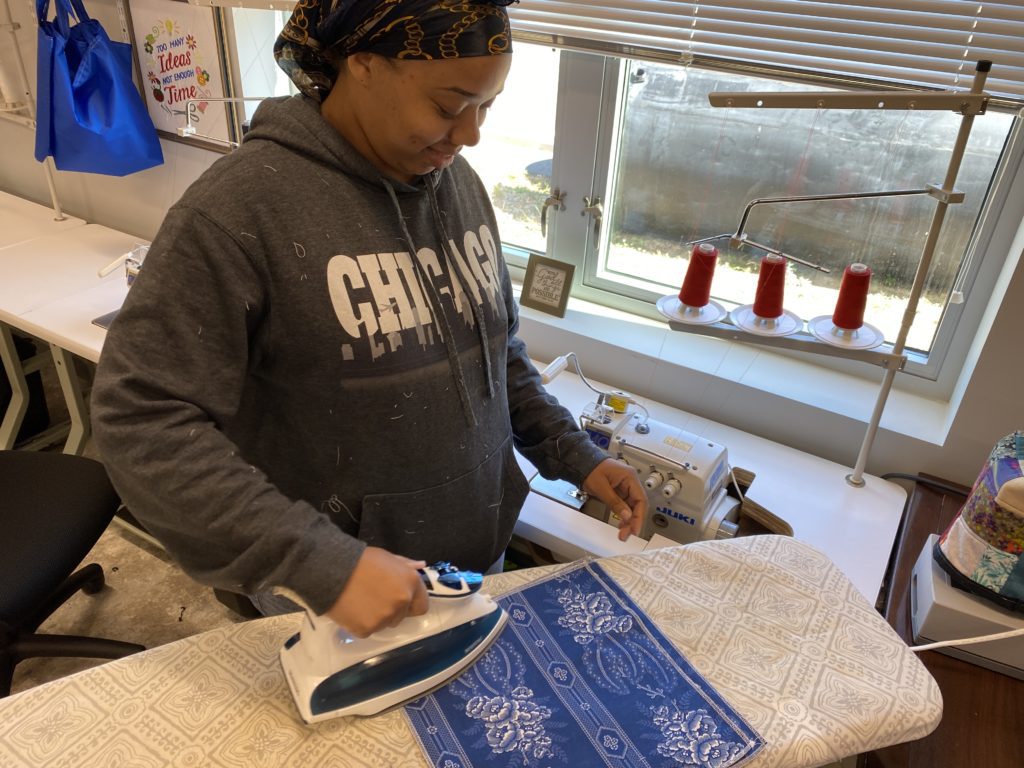

The industrial sewing class at A-B Tech is a five-days-a-week, four-week course, located on the bottom floor of Transformation Village. The first three weeks focus on stitching, and the last week is about career readiness. At the end of the course, Transformation Village holds a job fair for students to meet with local businesses and interview.

The program is open to anyone who wants to enroll, residents of Transformation Village as well as non-residents. The first cohort of five students finished in September of this year, and instructor Johnny Ko said he knows of one student who started a job immediately at IFB Solutions, and two others who have interviews lined up for employment.

Ko is a retired dentist who moved to the area from Memphis and has always been a sewer. He was looking for a local place to donate fabric and happened upon ABCCM. They asked immediately if he was interested in teaching a volunteer class. He has been doing this work for the last two years, but has now added A-B Tech’s program to his schedule.

“This is a career path for women from the facility as well as outside students,” Ko said. He is creating relationships with those hiring, and he’s hoping to schedule field trips to the companies that participate in the job fair.

He wants to expose students to different work environments and allow them to see firsthand the types of products these manufacturers are making. In visiting facilities, students can get a feel for what it’s like to work there, hopefully removing one barrier to entry.

The second cohort began in mid-October and Ko said three more sessions are planned. Of the four students we met, one is an employee of Diamond Brand and is taking the class to learn more skills. The rest are seeking employment.

Caprice Walker found the class in doing online research. She grew up in Chicago and didn’t know of sewing job opportunities in Asheville, but has always been interested in the craft.

Tals Lombardo found out about A-B Tech’s industrial sewing the same way. She came in with the goal of learning these sewing skills and then plans on applying to work at Sew Co. in Asheville.

Jennifer Begtrup is a resident of Transformation Village and said she started taking the volunteer sewing classes because Ko makes it so fun. She wanted to take her skills a step further, so she enrolled in industrial sewing. She said the class is “life changing.”

“This whole experience has opened up a lot of doors inside here, and it’s gonna be fun to see where it leads me out there.”

Jennifer Begtrup, Industrial Sewing student at A-B Tech

Cronin said the impact has been immediate. Having the program in the building removes a large barrier most people face when it comes to access: transportation. She said the residents in the program walk down the hallway with more self confidence and with big beautiful smiles on their faces.

The industrial sewing program and the people that teach it all contribute to this change.

Cronin believes: “It just gives these women hope.”